Maximum Weight per Piece 5 tons

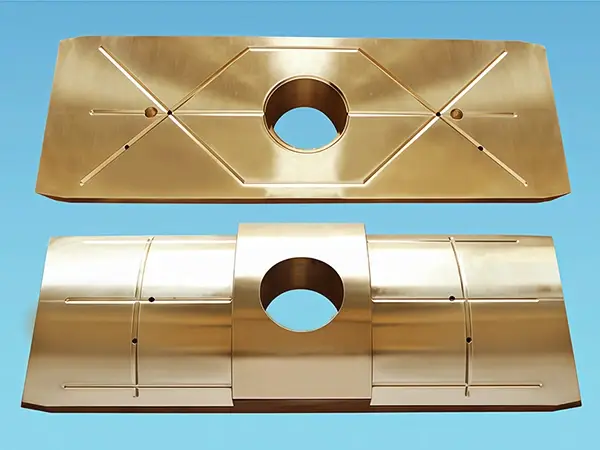

Bronze slippers are widely used in machinery where parts need to move smoothly while carrying heavy loads. They’re usually made from copper alloys such as bronze or brass, materials known for their durability and stable sliding performance. Each slipper is cast using the centrifugal method, giving it a dense structure that resists friction and prevents surface sticking during operation. In some cases, graphite or other solid lubricants can be added to the surface to improve lubrication and extend service life, especially in equipment that runs under high pressure or limited maintenance conditions.

Bronze slippers are mainly made from copper alloys with added elements such as tin, aluminum, or iron to improve strength and performance.

Two of the most used alloys are C95800 and C90710, each suitable for different operating conditions.

| Material No. |

|

|

| Category | High-strength aluminum bronze | Leaded tin bronze |

| Core Features | • High tensile strength (800–950 MPa) • Excellent corrosion resistance • Stable performance at 300–350 °C |

• Easy to machine (Ra ≤ 1.6 µm) • Good formability • Reliable wear resistance under medium or low loads |

| Typical Applications | Used in mining equipment, marine propellers, high-pressure valve cores, and drilling machinery bushings | Suitable for precision bushings, high-accuracy bearings, light-duty sliding components, and electronic connector terminals |

Bronze slippers are mainly used in steel industry equipment, particularly in rolling mill systems, as they help reduce friction, guide motion, and ensure smooth operation under heavy loads.

We handle every production stage independently, from the development and casting of bronze wear parts to machining and quality inspection. This allows us to have full control over product quality and ensures that each process is backed by our proprietary know-how and patented technologies.

Backed by more than 40 years of experience, we specialize in bronze wear parts for wind power, mining, hydropower, marine, and oil extraction equipment. Our product catalog includes bronze and steel bearings, bushings, and other wear components. We have long-term partnerships with several Fortune 500 companies within these industries.

Our workshop is equipped with 20 advanced five-axis machining centers from MAZAK and MAKINO, along with 35 imported turning and milling machines. The 5,000 m² temperature-controlled facility is operated by experienced CNC technicians who make sure every part is machined with accuracy and consistency.

We manage every step of production in-house, following ISO9001 and CCS quality standards to ensure consistent results. Our CNAS-accredited laboratory (CNAS L5937) and skilled inspection team handle all testing and verification, including material composition, hardness, tensile strength, and microstructure, along with non-destructive tests such as UT, PT, and VT. All procedures comply with GB, ASTM, ISO, JIS, and YS standards.

From bronze bushings and bearings to customized wear components, we’re here to help you find the right solution for your equipment.

Bronze bearings with solid lubricants can be provided for high-pressure compressor systems. Using a composite design that combines a copper alloy base with embedded lubricating materials, these bearings offer high wear resistance, self-lubricating performance, and reliable operation under extreme conditions with little or no maintenance.

When evaluating new suppliers, buyers usually check ISO9001 quality management, environmental and safety certifications, material traceability, and other industry-specific approvals to ensure product reliability and compliance.

Bronze eccentric bushings are made from high-lead bronze alloys such as ZCuPb10Sn10, ZCuPb15Sn8, and ZCuPb20Sn5. These alloys provide excellent self-lubricating, anti-seizing, and wear-resistant properties, allowing stable performance even under strong impact and heavy dust exposure. The wear resistance can also be enhanced through customized designs to meet the demands of abrasive working conditions.

Bronze nuts and slippers are produced from high-strength copper-based alloys that offer excellent resistance to seawater corrosion. These alloys retain their mechanical integrity and surface stability over time, making them well suited for continuous operation in marine, humid, or chemically active environments.

High-precision bushings are manufactured through centrifugal casting, five-axis CNC machining, and polishing. With strict quality control and CNAS-certified testing, tolerance accuracy reaches ±0.025 mm and surface roughness Ra ≤ 0.8 μm, meeting the standards required for CNC systems.