Maximum Size Width 500 mm

Maximum Size Thickness 50 mm

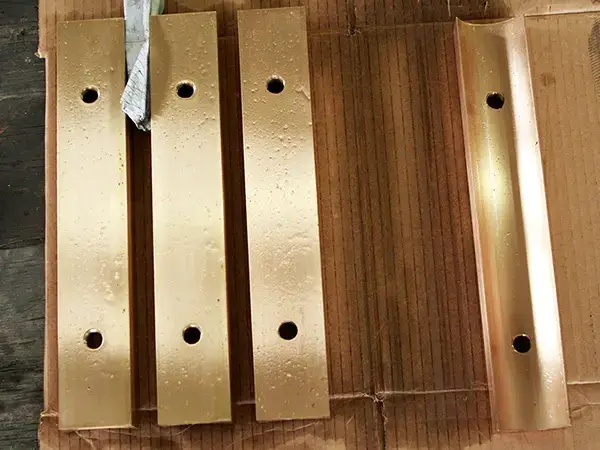

Bronze wear plates are flat sliding wear parts made from copper alloys, used to reduce friction and guide moving components in various types of machines. They’re commonly found in molds, mechanical guide rails, and other equipment that require smooth and precise movement. Wear plates combine good thermal and electrical conductivity with excellent corrosion resistance. Many of them feature self-lubricating properties thanks to solid lubricants like graphite or molybdenum disulfide embedded in the bronze. During operation, these lubricants gradually release to form a thin protective film that minimizes friction and wear.

In industrial settings, bronze wear plates are used as guiding and supporting components in equipment such as presses, forging machines, rolling mills, and sliding bases. They help keep parts aligned and ensure smooth, steady movement under heavy loads. Durable and cost-effective, wear plates are a good choice for applications that need consistent performance and long service life.

Bronze wear plates and guide plates are available in various sizes and configurations, tailored to different requirements. There are various bronze alloys available, including C86300 and C83600, each selected based on its specific performance characteristics.

| Material No. |

|

|

| Category | Manganese Bronze | Leaded Tin Bronze |

| Core Properties | • High shear strength and excellent fatigue resistance • Withstands long-term impact and vibration loads • Tensile strength: 550–700 MPa, elongation ≥ 15% |

• Excellent wear resistance and anti-seizing properties • Stable casting performance and good machinability • Tight dimensional control after forming |

| Typical Applications | Used for couplings, automotive and engineering shock absorber parts, and flexible joints in marine equipment. | Used for gears, worm wheels, shafts, bearing bushes, and industrial nuts and bolts. |

Bronze wear plates are widely used in various industries, including lifting presses, truck braking and suspension systems, steel rolling mills, hydraulic machinery, forging equipment, and metalworking. They are also used in the automotive, steel, and power generation sectors.

We handle every production stage independently, from the development and casting of bronze wear parts to machining and quality inspection. This allows us to have full control over product quality and ensures that each process is backed by our proprietary know-how and patented technologies.

Backed by more than 40 years of experience, we specialize in bronze wear parts for wind power, mining, hydropower, marine, and oil extraction equipment. Our product catalog includes bronze and steel bearings, bushings, and other wear components. We have long-term partnerships with several Fortune 500 companies within these industries.

Our workshop is equipped with 20 advanced five-axis machining centers from MAZAK and MAKINO, along with 35 imported turning and milling machines. The 5,000 m² temperature-controlled facility is operated by experienced CNC technicians who make sure every part is machined with accuracy and consistency.

We manage every step of production in-house, following ISO9001 and CCS quality standards to ensure consistent results. Our CNAS-accredited laboratory (CNAS L5937) and skilled inspection team handle all testing and verification, including material composition, hardness, tensile strength, and microstructure, along with non-destructive tests such as UT, PT, and VT. All procedures comply with GB, ASTM, ISO, JIS, and YS standards.

From bronze bushings and bearings to customized wear components, we’re here to help you find the right solution for your equipment.

Inspection and testing reports can be issued according to railway industry standards. All reports follow ISO9001 and CNAS certification requirements to guarantee accuracy and reliability.

Bronze bearings with solid lubricants can be provided for high-pressure compressor systems. Using a composite design that combines a copper alloy base with embedded lubricating materials, these bearings offer high wear resistance, self-lubricating performance, and reliable operation under extreme conditions with little or no maintenance.

When evaluating new suppliers, buyers usually check ISO9001 quality management, environmental and safety certifications, material traceability, and other industry-specific approvals to ensure product reliability and compliance.

Bronze eccentric bushings are made from high-lead bronze alloys such as ZCuPb10Sn10, ZCuPb15Sn8, and ZCuPb20Sn5. These alloys provide excellent self-lubricating, anti-seizing, and wear-resistant properties, allowing stable performance even under strong impact and heavy dust exposure. The wear resistance can also be enhanced through customized designs to meet the demands of abrasive working conditions.

Bronze nuts and slippers are produced from high-strength copper-based alloys that offer excellent resistance to seawater corrosion. These alloys retain their mechanical integrity and surface stability over time, making them well suited for continuous operation in marine, humid, or chemically active environments.