We use high-purity metal materials (99.99%) to produce our bronze sliding bearings. Each alloy composition is adjusted according to performance standards and customer requirements, then processed through our proprietary centrifugal casting technology. Before production begins, every batch of bronze material is tested and recorded to ensure consistency and traceability. Sample materials are kept for up to five years (or longer if requested by the customer) to guarantee product reliability and accountability over time.

All manufacturing processes are carried out in full compliance with the ISO9001 quality management system and CCS (China Classification Society) requirements. Every production step is closely monitored to ensure product consistency and reliability.

Vertical Machining Equipment: Maximum outer diameter: 4000 mm, maximum weight: 22 tons per piece

Five-Axis Machining Centers: 8 units from MAZAK (Japan), precision ±0.01 mm

Horizontal Machining Centers: 2 units from Makino (Japan), precision ±0.005 mm

Horizontal Lathes: 2 units from MAZAK (Japan), 1 from IKEGAI (Japan), and 1 from OKUMA (Japan), all with precision ±0.005 mm

Vertical Lathes: 11 units in total from OM (Japan), MAZAK (Japan), and DOOSAN (Korea), precision ±0.01 mm

Five-Face Machining Center: 1 unit from NICOLAS CORREA (Spain), precision ±0.015 mm

Vertical Machining Center: 1 unit from Makino (Japan)

Large and Medium-Sized Lathes: 1 unit with a 160 mm chuck and 1 unit with a 130 mm chuck

Other CNC Machines: Over 60 units for various precision machining operations

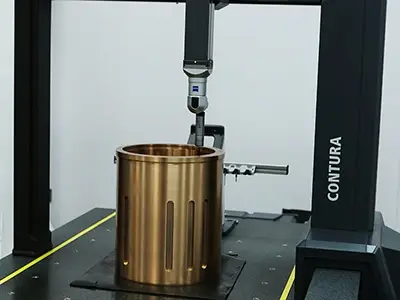

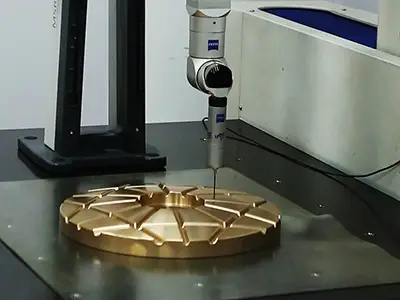

We put great importance on quality and use advanced inspection equipment to make sure every product meets consistent and reliable standards. Our central laboratory was accredited by CNAS (CNAS L5937) in 2012 and recognized by ILAC-MRA, meaning our testing results are accepted in more than 105 countries and regions. Our inspection process covers different aspects, including the metal’s composition, hardness, tensile strength, and structure, along with non-destructive tests such as ultrasonic (UT), penetrant (PT), and visual testing (VT). All processes are carried out in accordance with GB, ASTM, ISO(E), JIS, and YS standards. We use imported testing instruments and performance evaluation systems to make sure every product meets strict standards for accuracy and reliability before it leaves our facility.

We take environmental responsibility seriously by following EU carbon emission standards throughout our production. Each year, we monitor our carbon footprint and set new goals to further reduce it. We also voluntarily join third-party clean production audits organized by the government. Over the past decade, we’ve completed three rounds of audits that thoroughly evaluated our environmental performance and energy efficiency. These efforts help us work in line with environmental regulations, use resources more wisely, and cut down on pollution and waste. They also help us grow responsibly and keep our business strong for the long run.

All these efforts reflect our strong commitment to quality and our drive to stay ahead in the copper alloy bearing industry. We keep improving our manufacturing and design capabilities to meet our customers’ changing needs, delivering products that are reliable, consistent, and built to last.

At Yongcheng, our guiding principle is to earn our clients' trust through honesty, great service, and dependable quality. We obtained the ISO9001 certification in 2001 and CCS quality certification in 2010, which are proof of our commitment towards higher standards. From raw materials to production, final inspection, and continuous product improvement, we make sure every detail reflects our dedication to excellence.